The T*Star.Control package provides a complete set of reporting functions and automation analysis tools of distributed control systems. It provides transparency of the manufacturing & operational processes for operators, engineers and managers. Hereby opening the way to new insights and opportunities for your organisation. Only limited technical knowledge is required, as this application strives to display intuitive graphical schemes and data grids.

Based on a Web interface with Big Data database, a broad scope of control reports, verification checks, control change management and graphic diagramming is provided. All data is collected automatically based on a schedule that is tuned to its functionality and change rate.

The unique power of T*Star.Control is the combination of different control systems and the centralization of all major control streams:

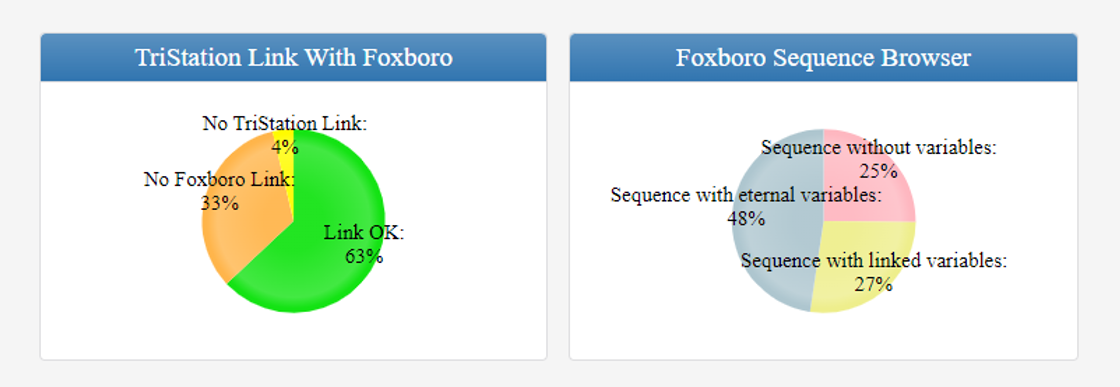

Some of the different control systems that we support are Siemens, Delta V (Emerson), Honeywell, Foxboro and Yokogawa.

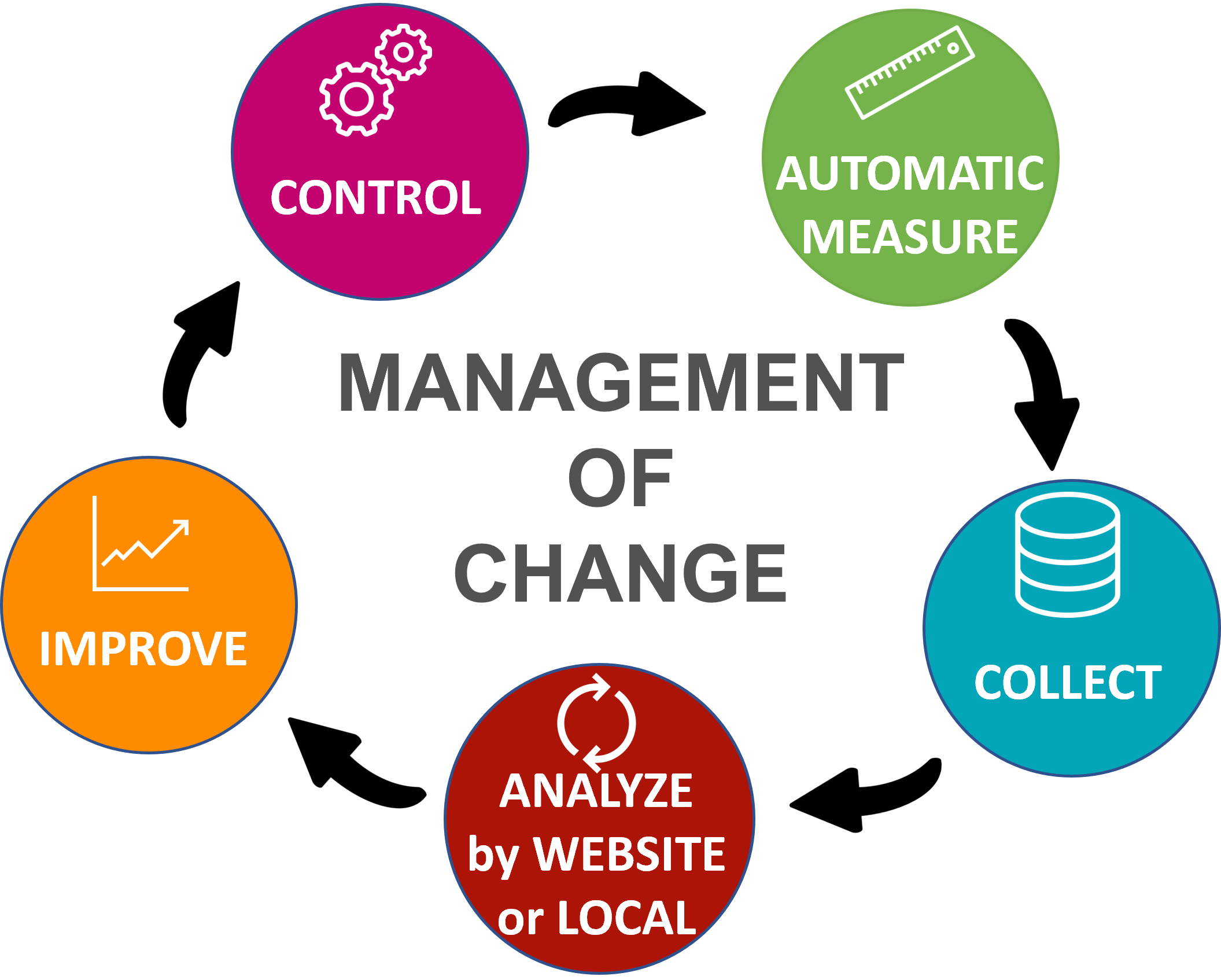

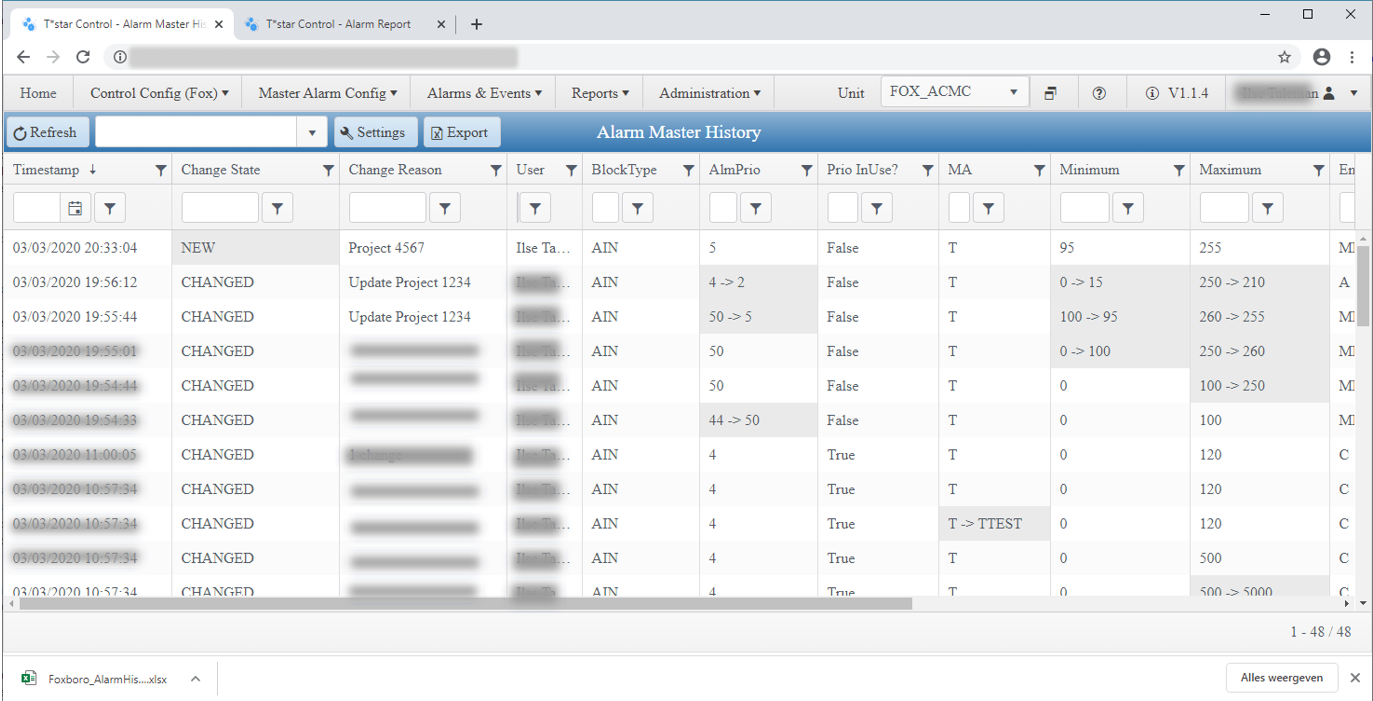

Management Of Change (MOC) ensures that the risks involved with permanent or temporary changes to the control system can be monitored. Also changes during the unit operation phase can be controlled through MOC. Start with MOC without updating it manually! T*Star.Control collects automatically control and system changes. Thanks to these automatic collections, a reliable and up-to-date history reporting tool is provided for your organization. Based on smart interpreters, T*Star.Control can recognize and alert the most crucial hazards and risks. The possibility to attach custom reasons and notes to each change provides a clear and transparent history report of your control system. Reports of all changes are available through the T*Star.Control website, e-mail notifications and Excel.

The Master Alarm Database (MADB) table is an authorized list of rationalized alarms and associated attributes. It forms the bridge between the alarms and the alarm management philosophy, ensuring the integrity of the alarm system and serves as an input for future alarm execution strategies. T*Star.Control gathers all alarms, events and messages from all your automation systems. More than 20 years of experience in communicating with DCS systems and collecting process alarms, events and messages shows that T*Star.Control is fast, reliable and secure. Through our automatically updated Wizard button, alarm settings are initially easily created. Further editations on alarm settings are automatically historized with the possibility to add a custom reason. From this MADB table, an alarm report can be generated. This alarm report contains an overview of the changes and similarities between MADB values & CP values, and between the alarm configuration & CP values.

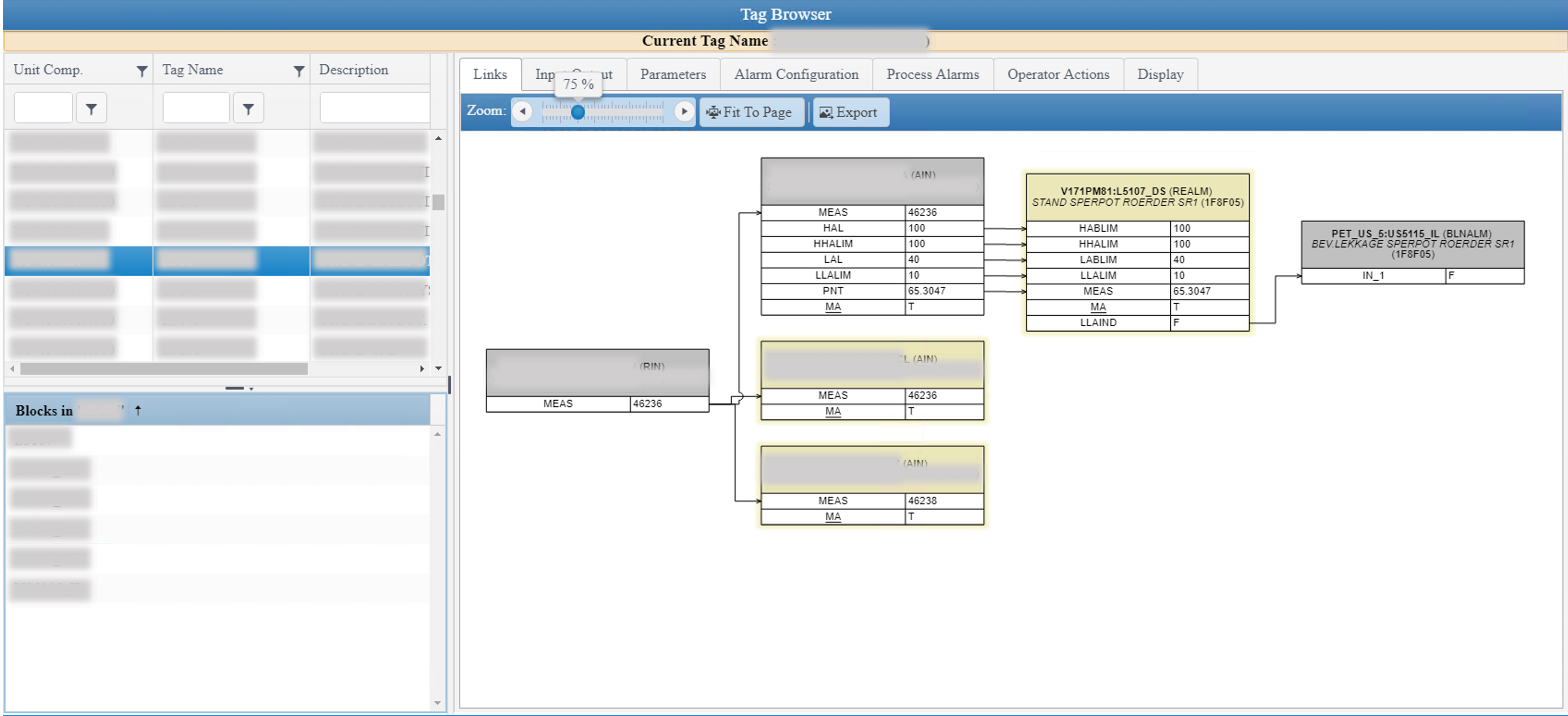

T*Star.Control gives you access to tag parameters, their connections to other tags and which displays contain which tags. Also, The internal logic scheme of a tag can be accessed through logial function plans. Furthermore, the real physical address connection of a tag is also displayed. With this module, the input/output card connections show which points are available and which are in use.

Verification checks to assist the engineer in solving control system missing links, duplicates, type errors, invalid parameter configurations and issues in order to avoid system instability. T*Star.Control generates all this information automatically for your organisation.

T*Star.Control consists of several building blocks and interfaces. Our software is designed to be personalized & adapted to your organisation.